Different methods of precooling

➢cold air (room cooling, forced air cooling),

➢cold water (hydrocooling),

➢direct contact with ice (contact icing),

➢evaporation of water from the produce (evaporative cooling, vacuum

cooling) and

➢combination of vacuum and hydrocooling (hydrovac cooling).

I) Room cooling:

➢ It is low cost and slow method of cooling.

➢ In this method, produce is simply loaded into a insulated cool room and cool

air is allowed to circulate among the cartons, sacks, bins or bulk load.

Advantages:

➢ Produce can be cooled and stored at the same room thus saves on

handling costs

➢ No extra cost for pre-cooling equipment

➢ Suits for crops, which are marketed soon after harvest

Disadvantages:

➢ It is too slow method of cooling

➢ Space requirements for room cooling are more as compared to storage, thus loss of storage capacity

➢ Unsuitable for packed produce

➢ Excessive water is lost from the produce due to slow cooling.

- Horticulture crops suitable for rooms cooling are: Potato, onion, apple and citrus.

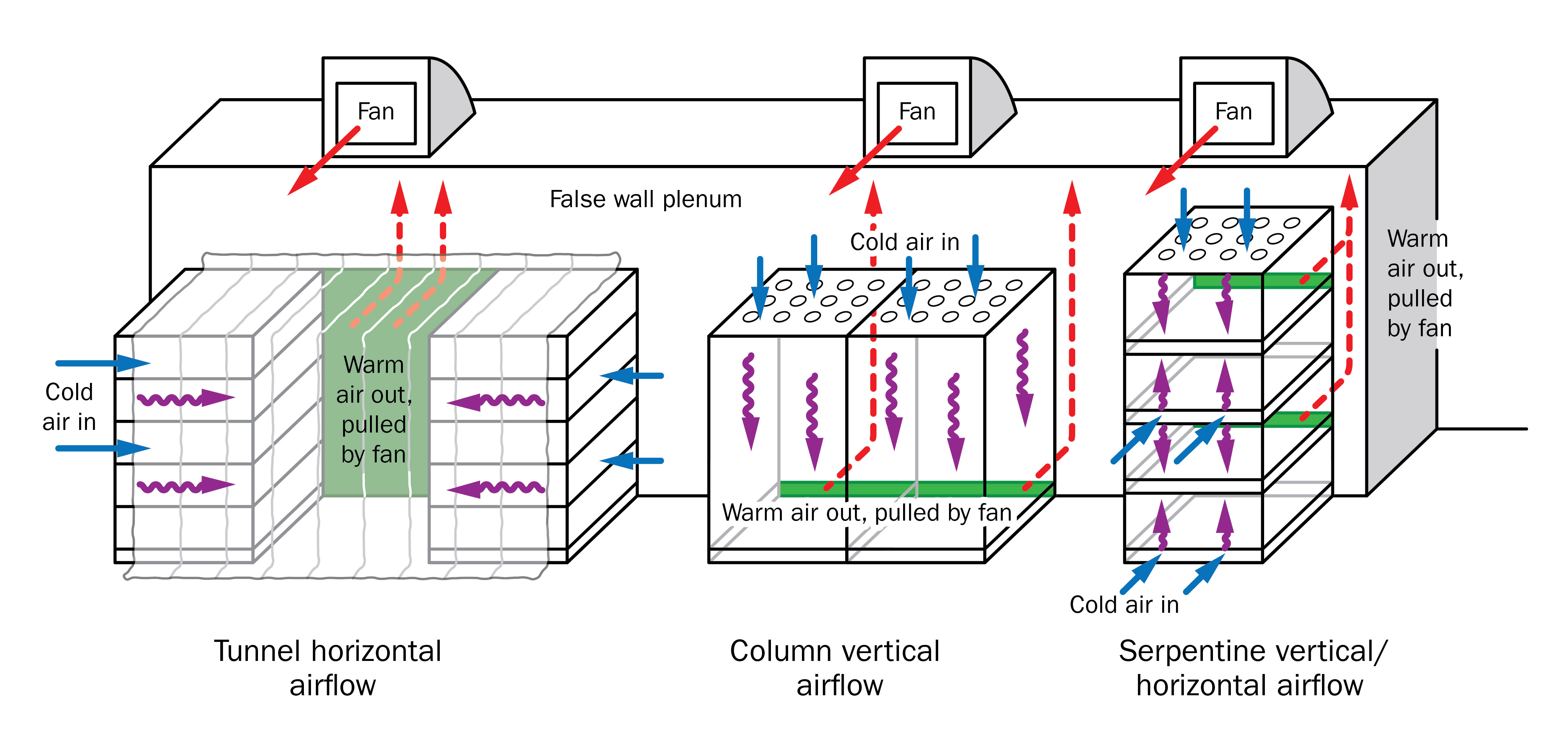

II) Forced-air cooling:

➢ Forced air-cooling is mostly used for wide range of horticultural produce

➢ This is the fastest method of pre-cooling

➢ Forced air-cooling pulls hot air or pushes cool air through the vents/holes in storage containers

➢ In this method uniform cooling of the produce can be achieved if the stacks are properly aligned.

➢ Cooling time depends on

(i) the airflow

(ii) the temperature difference between the produce and the cold air and

(iii) Amount of the produce

Advantages:

➢ Fast method of pre cooling (upto 90% faster than room cooling)

➢ Suitable for wide range of highly perishable commodities.

➢ Uniform cooling, if produce are properly aligned.

➢ Cooling times can be controlled for different types of produce by

controlling the air flow rate.

- Horticultural produce suitable for forced air cooling are: Grapes, Berries, Pears, Peach, Oranges, Strawberries tomato, and other tropical and subtropical fruits.

iii) Hydrocooling :

➢ cleaning and precooling at same time

➢ The use of cold water is an old and effective cooling method used for

quickly cooling a wide range of fruits and vegetables before packaging.

➢ For the packed commodities it is less used because

➢ difficulty in the movement of water through the containers and

➢ high cost involved in water tolerant containers.

➢ This method of cooling not only avoids water loss but may even add water

to the commodity.

➢ Some chemicals (nutrients/growth regulators/ fungicides) can also be mixed

with the water used in hydrocooling to prolong the shelf life by improving nutrient status of crop and preventing the spread of post-harvest diseases. The hydrocooler normally used are of two types :

➢ Shower type and Immersion type

Advantages:

- Less energy is used as compared to forced air cooling i.e. water removes

heat about 5 times faster than air

- Moisture loss does not take place.

Disadvantages:

- Most of the packages don’t tolerate wetting

- Wax layer of some fruits like pear, plum, apple is removed by using spray type of hydrocooler

- Horticultural produce suitable for hydrocooling are: Mango, peach, cherry, Asparagus etc. not suitable for berries, potato, onion etc

iv) Vacuum cooling:

➢ Vacuum cooling take place by water evaporation from the product at very low air pressure.

➢ In this method, air is pumped out from a larger steel chamber in which the produce is loaded for pre-cooling i.e. vacuum is created

➢ Removal of air results in the reduction of pressure of the atmosphere around the produce, which further lowers, the boiling temperature of its water.

➢ As the pressure falls, the water boils quickly removing the heat from the produce.

➢ Vacuum cooling cause about 1 per cent produce weight loss (mostly water) for each 60C of cooling.

Advantages:

- Fast and uniform cooling takes place.

- Most energy efficient method.

Disadvantages:

- High capital cost

- Produce losses more moisture

To overcome the more loss of water from the produce, another method of water spray vacuum is used, (modification of vacuum cooling), called hydro-vac cooling.

v) Package-icing :

➢In some commodities, crushed or flaked ice is packed along with produce for fast cooling.

➢However, as the ice comes in contact with the produce, it melts, and the cooling rate slows considerably.

➢The ice keeps a high relative humidity around the product.

➢Liquid icing distributes the ice throughout the container, achieving better contact with the product.

➢Packaged icing can be used only with water tolerant, non-chilling sensitive products and with water tolerant packages (waxed fiber board, plastic or wood)